Heavy-Duty Epoxy Solutions for large machinery warehouses

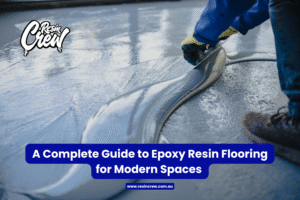

What Is Heavy Duty Epoxy Floor Coating?

Heavy-duty epoxy floor coating is a high-performance resin system applied to concrete floors. It creates a solid, seamless surface that can withstand significant mechanical stress, chemical exposure, and abrasion.

Key Features of Heavy-Duty Epoxy Floors:

- Machinery and vehicular traffic capabilities of loading strength

- Oil, fuel, solvent, and cleaning resistance Chemical resistance Chemical resistance to oils, fuels, solvents, and cleaners

- Non-skid Floor covering or safety assuring in wet or oily circumstances

- Hygienic design, easy-to-clean design

- Indoor/outdoor UV resistant in any environment and heat resistant

Why Epoxy Is Ideal for Machinery-Intensive Warehouses

Epoxy Coating Handles It All:

- Forklift traffic over extended periods

- Vibrations and shocks from mounted machinery

- Impact from dropped tools, pallets, or steel stock

- Temperature fluctuations in open bays or exposed loading docks

- Spill risks from hydraulic fluids, lubricants, and harsh solvents

Common Applications for Heavy Duty Epoxy Flooring

- Logistics and distribution centres

- Cold storage and food-grade facilities

- Automotive repair and service bays

- Industrial manufacturing floors

- Heavy equipment showrooms

- Aircraft hangars and aerospace production

Types of Epoxy Systems for Heavy Load Environments

3. Self-Levelling Epoxy

4. Heavy Duty Commercial Floor Levelling Epoxy

5. Heavy Duty Industrial Epoxy Flooring

Comparing Epoxy to Other Flooring Options

| Feature | Heavy Duty Epoxy | Polished Concrete | Tiles |

|---|---|---|---|

| Load Resistance | Excellent | Moderate | Poor |

| Chemical Resistance | High | Low | Varies |

| Maintenance | Low | Moderate | High |

| Repair Costs | Low | High (grinding) | High (retiling) |

| Safety (Anti-Slip) | Customisable | Low | Medium |

Benefits That Go Beyond the Surface

Improved Safety

Why Resin Crew Is Your Best Choice for Heavy-Duty Epoxy Flooring in Australia

- Decades of real-world experience in large-scale installations

- Expert consultation to choose the right epoxy system

- Fast, efficient application with minimal downtime

- Certified safety and durability standards

- Ongoing support for maintenance and re-coating when needed

Build a Stronger Business from the Ground Up

Heavy duty epoxy floor coating gives you peace of mind, better performance, and serious longevity. It’s a smart investment for any warehouse serious about efficiency, safety, and value.

Ready to upgrade your floors? Talk to the experts at Resin Crew today. Whether you’re building a new warehouse or upgrading an existing one, we’ll help you choose the perfect epoxy flooring heavy duty system to meet your operational needs. Fast quotes. Reliable service. Zero compromise.